Life Science Research Centers

The life sciences comprise the branches of science that involve the scientific study of organisms – such as microorganisms, plants, and animals including human beings – as well as related considerations like bioethics.

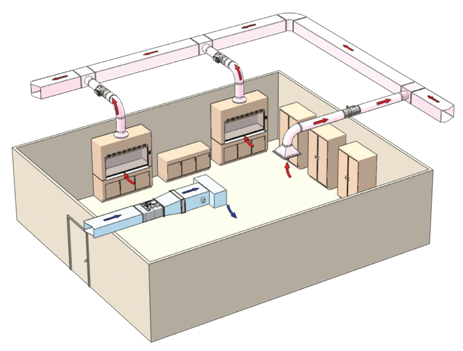

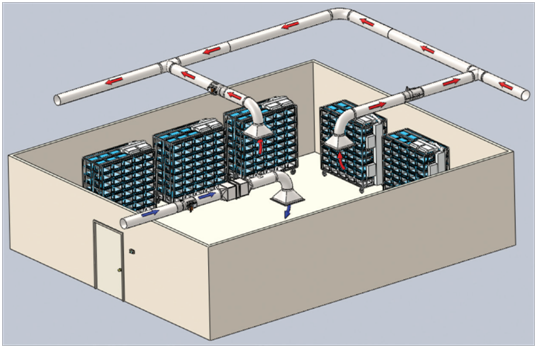

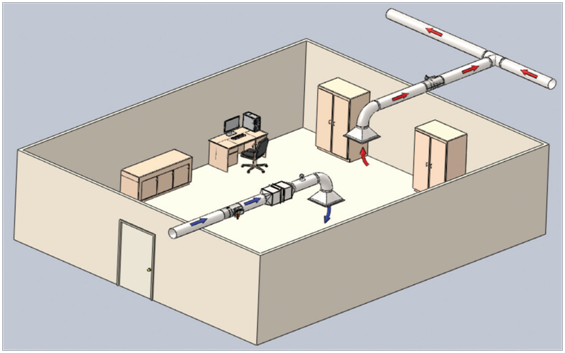

Life Science research centers in universities; biotech facilities and pharmaceutical research and manufacturing facilities, where tomorrow’s finest medicines and scientific practices are tested and refined; where ingenuity thrives, evolves and affects positive change. These centers, require more detailed and focused design engineering than most other types of laboratory environments. The ventilation system must create a safe, comfortable working environment for caregivers. It must ensure that contaminated and odorous air is exhausted and that correct room pressurization is maintained.